A History of Expertise and Innovation

RJ Lee Group has assessed environmental issues since the early 1980s when our Energy Technology Consultants (ETC) pioneered the recognition of specific air quality patterns. We developed a cutting-edge technique for identifying, measuring, and characterizing particles in the air using computer-controlled scanning electron microscopy (CCSEM).

RJ Lee Group has worked with clients in various industries, including the U.S. Environmental Protection Agency (EPA), to assess and provide solutions for environmental factors that could affect our health. Our services have grown over the years, from setting controls for unbound nanoparticles (UNP) to designing and building test chambers to simulate specific environmental conditions.

Today we offer our expertise for our clients’ environmental and compliance concerns and perform rigorous assessment and management of potential environmental risks.

LAB TESTING AREAS

Concrete and Construction Materials

Standardized and custom testing to evaluate performance, composition, and durability of cementitious systems - from field cores to lab-cast specimens.

At the forefront of concrete science, our Concrete Materials Department provides advanced analysis of hardened concrete, shotcrete, mortar, and raw materials. By integrating petrographic techniques with chemical and microstructural evaluation, we provide reliable data to inform engineering decisions, troubleshoot failures, and ensure compliance with project specifications. Our services support forensic investigations, new construction, and research and development.

What We Test

Cementitious Materials and More

Our laboratory specializes in evaluating concrete, mortar, grout, masonry, and related construction materials. Using standardized procedures and advanced instrumentation, we analyze samples from existing structures, new construction, or research programs.

Materials Tested:

- Field-extracted concrete cores

- Laboratory-cast concrete specimens

- Mortar, grout, and shotcrete

- Cement, fly ash, slag, silica fume, and other SCMs

- Aggregate for potential reactivity or quality concerns

Core Testing Capabilities

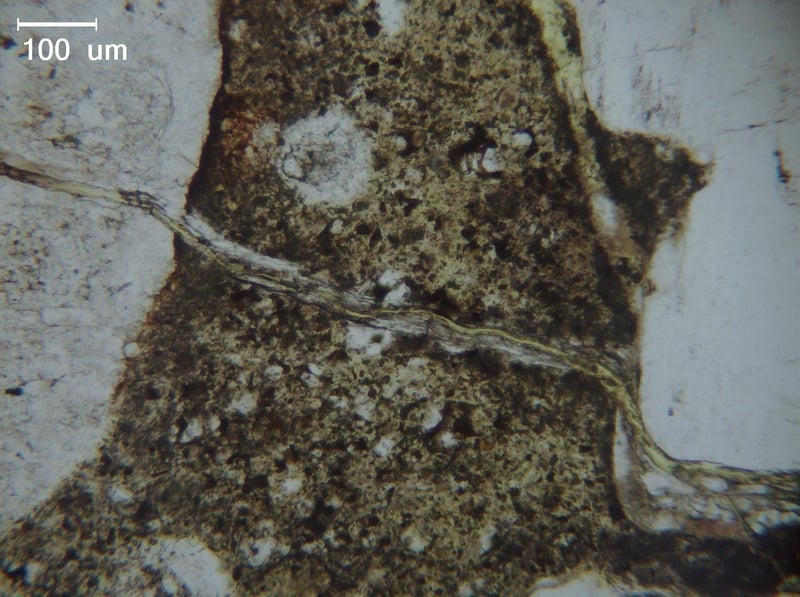

Petrographic Examination (ASTM C856, C295)

- Micrographic evaluation of deterioration (e.g., ASR, DEF, freeze-thaw)

- Elemental analysis of cement, SCMs, and aggregates

- Thin and polished section analysis

- Aggregate quality and mineralogy

- Assessment of hydration and microcracking

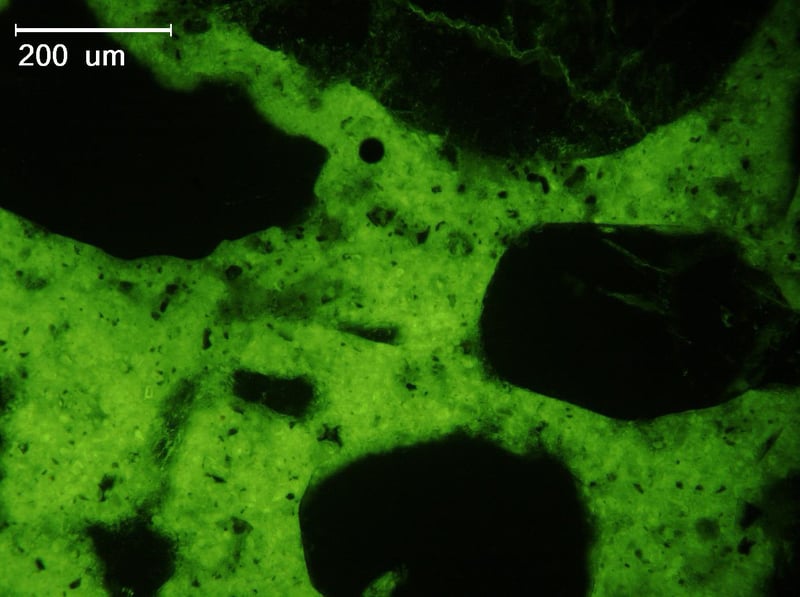

Air-Void System Analysis (ASTM C457)

- Measurement of total air content, spacing factor, and specific surface

- Assessment of freeze-thaw resistance potential

Chloride and Sulfate Content

- Acid-soluble chloride (ASTM C1152)

- Water-soluble chloride (ASTM C1218)

- Sulfate content (ASTM C1580)

Water-Cementitious Ratio Estimation

- Fluorescent microscopy or BSE imaging

- Correlation with mix design and durability

Compressive Strength Testing

- Drilled core and cast cylinder specimens

- Surface preparation and dimensional compliance (ASTM C42, C39)

Advanced Instrumentation

Chemical and Microstructural Characterization

Our laboratory uses high-resolution tools to evaluate chemical composition, crystalline phases, and microstructural changes.

- Scanning Electron Microscopy with EDS (SEM/EDS): Crack patterns, ASR gel, hydration textures

- X-Ray Diffraction (XRD): Phase identification of crystalline compounds (e.g., portlandite, ettringite, gypsum, ASR gel)

- X-Ray Fluorescence (XRF): Elemental analysis of cement, SCM, and aggregates

- Chloride Content (ASTM C1152/C1218): Acid- and water-soluble chloride testing for corrosion risk assessment.

- Water-Soluble Alkalis: Measurement of available alkalis contributing to ASR susceptibility.

- FTIR (Fourier Transform Infrared Spectroscopy): Identification of surface coatings, curing compounds, and potential bond breakers.

Testing with Purpose

Designed to Support Engineering Decisions

Our laboratory results are designed not just to meet specifications, but to help solve problems. Whether you need forensic evaluation, materials qualification, or litigation support, we tailor testing to fit your project's goals.

Case study

How AeroTech Secured Its Future

When AeroTech Industries faced recurring defects in a crucial aircraft component, they were at risk of losing multi-million dollar contracts and jeopardizing the jobs of hundreds of employees. They enlisted the help of RJ Lee Group, who quickly deployed a team of technical experts. Through state-of-the-art forensic analysis, RJ Lee Group identified and rectified the root cause—a flaw in the casting process—eliminating the defect and preserving AeroTech's contracts.

expert spotlight

Michael Baker

Construction Materials Laboratory Manager

Michael Baker serves as the Department Manager of the Concrete Materials Laboratory and has nearly a decade of experience in concrete petrographic studies at RJ Lee Group. In addition to managing the concrete materials laboratory operations, he directs and conducts petrographic evaluations, in combination with chemical and physical testing, to identify failure and distress mechanisms in concrete and cementitious materials.

Let's Test it Right

Get to the root of your construction materials challenges with RJ Lee Group’s construction consulting services. Proactively analyze your minerals and construction materials and perform durability tests with us so that you can keep building confidently and safely. Schedule a chat with an RJ Lee Group Expert expert today.