Instrumentation

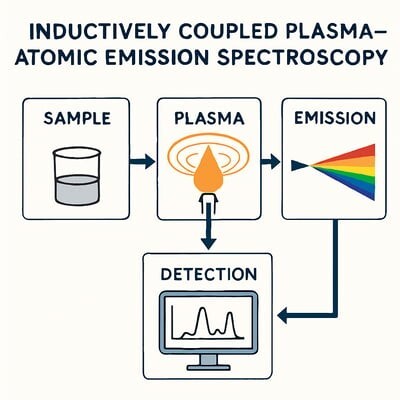

Inductively Coupled Plasma–Atomic Emission Spectroscopy (ICP-AES)

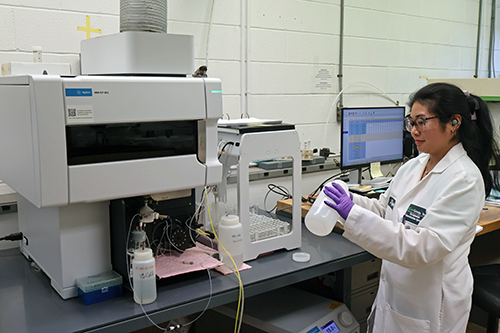

At RJ Lee Group, we deliver high-resolution elemental analysis to support industrial hygiene, environmental compliance, and product quality. Inductively Coupled Plasma–Atomic Emission Spectroscopy (ICP-AES) is one of our most trusted techniques for detecting and quantifying metals and trace elements in air, water, soil, and solid materials. Whether you're investigating contamination, validating product safety, or ensuring regulatory compliance, ICP-AES provides the sensitivity and reliability you need.

What is ICP-AES?

- Simultaneous multi-element detection.

- High throughput for routine analysis.

- Robust performance with complex matrices.

- Cost-effective for mid-level detection limits.

What Can You Do With ICP-AES?

RJ Lee Group uses ICP-AES for:

Industrial Hygiene

Analyze airborne metals in workplace exposure assessments using various OSHA and NIOSH methods. Utilizing hydrofluoric acid (HF) in a modified version of the NIOSH 7300 method to enhance the digestion and analysis of compounds such as aluminum oxide (Al₂O₃), titanium oxide (TiO₂) and Tungsten (W).

These oxides are typically resistant to conventional acid digestion techniques, but HF effectively breaks down their crystalline structures, allowing for accurate quantification of elemental aluminum and titanium using ICP-AES. This approach is particularly valuable in industrial hygiene assessments where precise detection of airborne particulates containing these compounds is critical.

Environmental Monitoring

Analyze a wide range of environmental matrices—including soil, water, paint, and surface wipes—for the presence of elemental pollutants such as aluminum, calcium iron, lead, magnesium, etc.

Characterizing raw materials and byproducts

Industries such as coal-fired power generation, chemical manufacturing, and materials processing produce a variety of residual and byproduct materials—including coal combustion residuals (CCRs) like fly ash and bottom ash, synthetic gypsum derived from flue gas desulfurization (FGD) systems, ceramics, polymers, and particulate matter collected from industrial dust control systems.

These materials often contain complex mixtures of trace and major elements—such as arsenic, selenium, mercury, aluminum, calcium, and silicon—that can influence their environmental impact, recyclability, and suitability for reuse in construction or manufacturing.

Support product development and quality control

ICP plays a critical role in manufacturing applications, particularly in the characterization and quality control of materials such as specialty glass and medical-grade components. For glass manufacturing, ICP-AES enables precise quantification of trace and major elements like silicon, boron, sodium, calcium, and transition metals.

In the medical device sector, the technique is used to analyze materials such as silicone elastomers and titanium alloys, ensuring biocompatibility and compliance with stringent regulatory standards. This elemental profiling supports both raw material validation and final product certification, helping manufacturers maintain consistency, safety, and performance across production batches

Ensure regulatory compliance with EPA, AIHA, FCC, USP and industry-specific standards.

Consumer Product Safety

ICP is employed to screen for regulated elements in consumer products such as paints, coatings, and household goods, ensuring compliance with safety standards set by agencies like the Consumer Product Safety Commission, EPA, and international bodies such as RoHS. This includes the detection and quantification of toxic metals like lead (Pb), cadmium (Cd), mercury (Hg), and chromium (Cr), which may pose health risks through dermal contact, inhalation, or ingestion.

The technique provides high sensitivity and multi-element capability, allowing for rapid assessment of complex matrices. In paints and coatings, helps identify heavy metal pigments or additives, while in household goods—such as toys, electronics, and cookware—it supports material safety evaluations and product recalls. This analytical approach is essential for manufacturers, importers, and regulatory bodies to ensure that products entering the market are safe for consumers and environmentally compliant.

Support other Departments within RJ Lee Group

- Construction Materials Testing - Assess cement, concrete, and aggregate for elemental consistency and performance.

- Corrosion and Failure Analysis - Identify elemental signatures associated with material degradation in infrastructure and manufacturing.

Our lab integrates ICP-AES with ICP-MS and other techniques to provide comprehensive elemental profiles across a wide range of matrices.

Why Choose RJ Lee Group for ICP-AES Analysis

RJ Lee Group is a recognized leader in analytical chemistry and industrial forensics. Our ICP-AES services are backed by:

- ISO 17025-accredited laboratory protocols.

- Validated methods for occupational and environmental testing.

- Customized reporting tailored to your regulatory and operational needs.

- Integrated services that combine ICP-AES with materials characterization, microscopy, and consulting.

Our team works closely with clients to ensure results are meaningful, actionable, and defensible.

Get in Touch

When precision and rapid results are critical, trust RJ Lee Group to deliver the insights you need. With decades of expertise in spectrographic analysis across diverse industries, we provide more than laboratory testing—we serve as your trusted partner in resolving complex challenges and delivering actionable solutions.

Blog

Read More

7 min read

Improving PFAS testing to meet today's most urgent needs: RJ Lee Group and Shimadzu Scientific Instruments, Inc.

October 01, 2024

4 min read

RJ Lee Group Brings IntelliSEM to Thermo Fisher Scanning Electron Microscopes

October 01, 2024