RJ Lee Group 9 min read

Full Particulate Characterization (FPC): Driving Quality and Innovation Across Industries

Contributors

RJ Lee Group

Subscribe to our newsletter

In today’s precision-driven world, understanding particulate matter isn’t simply beneficial—it’s essential. In many fields like pharmaceuticals, 3D printing, and environmental monitoring, particles provide important information about how well processes are working, how safe products are, how materials behave, and how well. At RJ Lee Group, our Full Particulate Characterization (FPC) services give organizations the clarity they need to troubleshoot effectively, maintain compliance, and innovate with confidence.

What Is Full Particulate Characterization?

Full Particulate Characterization (FPC) is a holistic evaluation of particles—foreign, intrinsic, or process-generated—within a product or material. Instead of focusing solely on identification, FPC provides a complete picture of morphology, composition, and behavior, while also revealing where particles originate and how they interact with surrounding materials. This level of insight requires a sophisticated combination of techniques and expertise, and RJ Lee Group brings together one of the most comprehensive capabilities in the industry to deliver it.

A Deep Bench of Instrumentation & Techniques

RJ Lee Group’s strength lies in our interdisciplinary approach—combining materials scientists, chemists, microscopists, forensic experts, and environmental specialists with an expansive suite of analytical technologies. This depth enables us to solve particulate problems that are too complex for general-purpose labs.

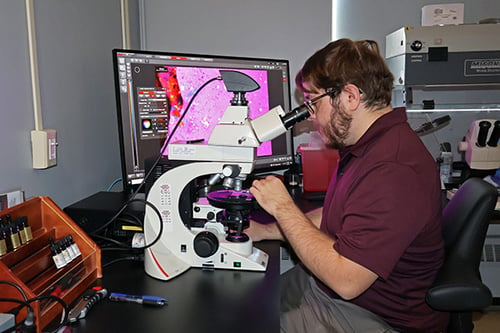

Microscopy & Imaging

Microscopy forms the foundation of particulate analysis, and our capabilities extend across the optical and electron spectrum:

-

Polarized Light Microscopy (PLM): Initial particle screening, morphology, birefringence, and contaminant classification

-

Scanning Electron Microscopy (SEM): Surface morphology at micro- and nanoscale

- Transmission Electron Microscopy (TEM): Ultra-high-resolution imaging for nanoscale materials, thin films, and complex particulates

RJ Lee Group transforms scanning electron microscopy by introducing true automation for particle analysis with IntelliSEM™. Designed for speed, accuracy, and ease of use, IntelliSEM automatically identifies and characterizes thousands of particles per hour, combining SEM and EDS technologies with advanced data analytics. Its intelligent software suite streamlines workflows with one-button setup, template-based reporting, and powerful visualization tools—delivering comprehensive insights while reducing manual effort.

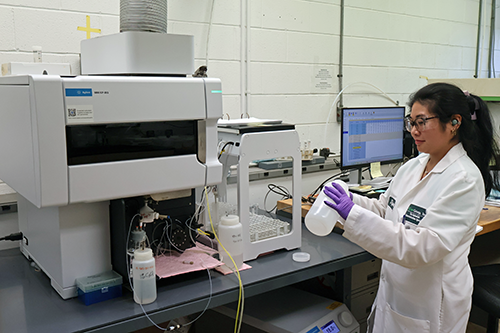

Elemental Analysis

Understanding elemental composition is essential for source attribution, contamination events, and material qualification. RJ Lee Group employs:

- Inductively Coupled Plasma (ICP) Techniques: Trace metal detection in liquids, solids, and environmental samples

- X-ray Fluorescence (XRF): Bulk elemental screening and compositional verification

- Energy Dispersive Spectroscopy (EDS): Elemental identification paired with SEM/TEM imaging

Chemical & Molecular Characterization

Chemical fingerprinting allows us to differentiate organic versus inorganic particulates and classify complex compounds. Techniques include:

-

Fourier Transform Infrared Spectroscopy (FTIR): Organic materials, polymers, coatings, pharmaceutical components

-

Raman Spectroscopy: Crystal structures, carbonaceous materials, pigments, and polymers

-

Gas Chromatography–Mass Spectrometry (GC-MS): Organic residues, extractables/leachables, volatile contamination

-

Thermal Analysis (DSC/TGA): Decomposition profiles, polymer behavior, residue characterization

Specialized Particulate & Materials Tools

For advanced or industry-specific challenges, RJ Lee Group brings additional capabilities rarely found under one roof:

- X-ray Diffraction (XRD): Crystalline phase identification

- Automated Particle Classification Systems: IntelliSEM Automated Particle Analysis software and ParticleID particle identification database.

This integrated toolkit enables us to characterize particles from every angle: visually, chemically, structurally, and behaviorally.

Industry Applications: Why FPC Matters

Particulate analysis is important in many fields, and the information it gives can help avoid expensive problems or legal issues.

Pharmaceuticals

In the pharmaceutical industry, particulate contamination poses one of the most significant risks to product safety. RJ Lee Group’s team has a lot of experience looking into problems when products don’t meet standards, figuring out where particles come from, and helping companies follow FDA and Our scientists regularly assist with root-cause investigations, raw material evaluations, and contamination studies, ensuring that manufacturers can protect their processes and, ultimately, their patients.

Additive Manufacturing

Additive manufacturing and 3D printing rely heavily on powder quality, and variations in particle morphology or composition can dramatically influence build success. Our advanced microscopy and materials analysis capabilities help manufacturers characterize powders, detect impurities, and refine new material formulations. By combining particle imaging, chemical analysis, and size-distribution techniques, we help AM teams maintain consistency and reduce risk in both production and R&D environments.

Environmental Health & Safety

Environmental and sustainability initiatives also depend on accurate particulate characterization. RJ Lee Group offers the scientific support needed for meeting regulations, assessing the environment, and conducting investigations, whether it's looking at air pollution, industrial waste, or particles in water and soil. Our experienced environmental scientists and microscopists work together to identify sources, mechanisms, and environmental impacts, offering clear data that supports permitting, mitigation, and long-term planning.

Why RJ Lee Group Is Uniquely Positioned for FPC

What truly makes RJ Lee Group unique is not any single instrument, but the convergence of technology, software, expertise, and investigative depth. Our team includes materials scientists, chemists, microscopists, environmental specialists, industrial hygienists, and forensic experts—each contributing specialized knowledge that enriches every investigation. This interdisciplinary structure enables us to approach particulate problems from multiple angles, ensuring that our conclusions are scientifically rigorous, legally defensible, and practical for real-world decision-making.

Because we offer so many complementary analytical capabilities under one roof, we can pursue the full story behind a particle—not just what it is, but how it formed, what it interacted with, why it matters, and what steps should be taken next. Chemical and molecular characterization at the integration level is rare, which enables us to confidently support clients in highly regulated industries.

Looking Ahead

As materials become more engineered and manufacturing processes more sophisticated, the demand for precise particulate characterization will only increase. From safeguarding pharmaceutical products to developing next-generation materials and supporting environmental stewardship, FPC plays a critical role in ensuring safety, quality, and innovation.

As materials become more engineered and manufacturing processes more sophisticated, the demand for precise particulate characterization will only increase. From safeguarding pharmaceutical products to developing next-generation materials and supporting environmental stewardship, FPC plays a critical role in ensuring safety, quality, and innovation.

At RJ Lee Group, we don’t simply analyze particles—we help our clients understand what those particles say about their processes and their products. Whether solving a contamination event, validating a manufacturing line, or advancing research, our multidisciplinary team is ready to partner with you.

Ready to Strengthen Your Quality and Compliance Programs?

Contact RJ Lee Group to learn how our Full Particulate Characterization services can support your goals in quality, safety, and innovation.