LAB TESTING AREAS

Crystalline Silica Analysis

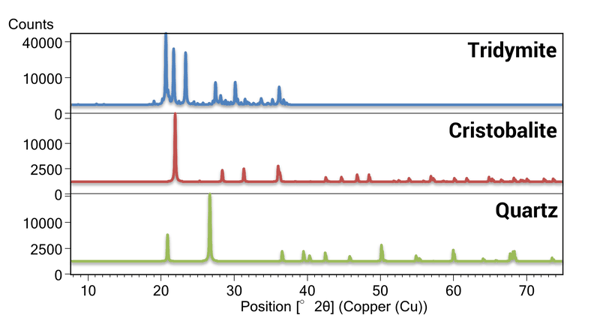

RJ Lee Group specializes in X-ray Diffraction (XRD) analysis for crystalline silica—delivering precise phase identification and quantification of quartz, cristobalite, and tridymite in both air and bulk samples. Our laboratory supports compliance with OSHA, MSHA, and NIOSH regulations, using state-of-the-art instruments to achieve low detection limits, high resolution, and rapid turnaround times.

Industries such as mining, construction, manufacturing, and industrial hygiene rely on our services to monitor worker exposure, validate Safety Data Sheets (SDS), and ensure regulatory compliance. Whether assessing airborne respirable crystalline silica (RCS) in occupational settings or verifying bulk material composition, our testing helps mitigate health risks, and supports litigation, product safety, and environmental remediation efforts.

Crystalline Silica Analysis by XRD

Crystalline silica is a naturally occurring mineral found in materials such as sand, soil, granite, and construction products like concrete, glass, ceramics, and engineered stone. When these materials are cut, ground, or drilled, they can release respirable crystalline silica dust—a known health hazard linked to silicosis and other lung diseases.

Why Perform Crystalline Silica Testing?

Testing your product or bulk material is essential to:- Protect worker health and safety

- Comply with OSHA labeling and exposure regulations

- Understand the silica content in your raw materials or finished products

Crystalline Silica Testing by RJ Lee Group

Our XRD lab for crystalline silica in Monroeville, PA offers comprehensive quantitative silica analysis with unmatched sensitivity and accuracy. Our testing includes all three regulated forms of crystalline silica:

- Quartz

- Cristobalite

- Tridymite

Why Choose RJ Lee Group for XRD Silica Testing

- True Bulk Analysis – We analyze 1–2 grams or more of material to ensure results are representative of the entire sample.

- Lowest Detection Limits in the Industry – Our advanced techniques achieve detection limits as low as 0.1% or lower, even in complex mineral matrices which cause interferences in the XRD scans.

- Matrix Reduction for Accuracy – Using specialized heat and acid digestion methods, we reduce the sample matrix prior to analysis to eliminate interferences and enhance sensitivity.

- Expertise with Interfering Minerals – Our sample preparation methods are effective even when crystalline silica is present alongside minerals like mica, clay, feldspar, and barite which cause interferences in the XRD scans.

- Specialized Identification – We also offer a unique XRD method to distinguish between opal and cristobalite, helping you solve complex silica-related challenges.

- Fast turnaround times- We offer a standard 10 working day turnaround time with quicker times available on request. Our lab has 4 Malvern Panalytical XRD instruments on-site, ensuring that instrument repairs will not slow down the receipt of your results.

A History of Expertise and Innovation

RJ Lee Group has assessed environmental issues since the early 1980s when our Energy Technology Consultants (ETC) pioneered the recognition of specific air quality patterns. We developed a cutting-edge technique for identifying, measuring, and characterizing particles in the air using computer-controlled scanning electron microscopy (CCSEM).

RJ Lee Group has worked with clients in various industries, including the U.S. Environmental Protection Agency (EPA), to assess and provide solutions for environmental factors that could affect our health. Our services have grown over the years, from setting controls for unbound nanoparticles (UNP) to designing and building test chambers to simulate specific environmental conditions.

Today we offer our expertise for our clients’ environmental and compliance concerns and perform rigorous assessment and management of potential environmental risks.

Advanced Respirable Crystalline Silica Analysis

For a more complete picture, RJ Lee Group can combine total crystalline silica analysis by XRD with particle size testing such as Stokes sedimentation, NEN/SWFF or CCSEM to determine the amount of respirable crystalline silica in your material.

Get in Touch

Ready to ensure your materials meet safety and regulatory standards? Contact us to learn more about our crystalline silica testing services or to request a quote.