Instrumentation

X-Ray Fluorescence (XRF)

X-ray Fluorescence (XRF) is a fast, non-destructive technique used to identify the elemental composition of materials—such as metals, minerals, and ceramics. It’s widely used across industries for its speed, accuracy, and ability to analyze samples without causing damage.

What is XRF?

X-ray Fluorescence (XRF) spectroscopy is a non-destructive analytical technique used to determine the elemental composition of materials.

How Does it Work?

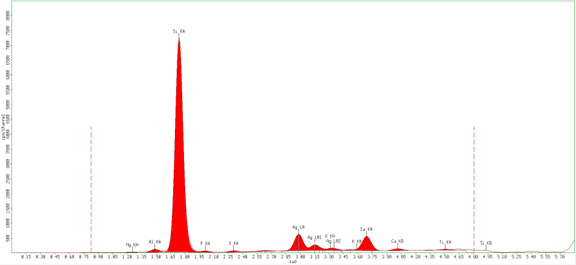

When a sample is exposed to high-energy X-rays, its atoms become excited and emit secondary (fluorescent) X-rays. The energy signatures of these emissions are unique to each element, enabling accurate identification and quantification of the materials' chemical constituents.

What Can You Do With XRF?

XRF testing, a powerful non-destructive testing method, is widely used for elemental analysis and material composition analysis across various industries.

- Geology and Mining: Analyze rock, mineral, and soil samples for exploration and resource assessment using precise XRF testing techniques.

- Environmental Science: Detect and quantify pollutants in soil, sediment, and water through advanced elemental analysis.

- Art & Archaeology: Determine the elemental composition of artifacts and historical materials without damaging valuable specimens.

- Manufacturing: Ensure quality control of raw materials and finished products with reliable, non-destructive testing methods.

- Glass Analysis: Assess the chemical composition of glass to ensure quality, performance, and compliance with industry standards.

Why Choose RJ Lee Group for XRF Analysis?

We offer a comprehensive suite of X-ray fluorescence (XRF) testing services to meet the needs of industries ranging from materials science to environmental analysis.

Our Capabilities Include:

- Energy Dispersive XRF (EDXRF)

- Wavelength Dispersive XRF (WDXRF)

- Portable XRF Analysis for on-site testing

Our standard XRF analysis spans a wide range of elements across the periodic table and includes Loss on Ignition (LOI) testing for fast, accurate chemical composition results.

Enhanced Element Detection

Need to detect light elements such as carbon (C), hydrogen (H), nitrogen (N), lithium (Li) or boron (B)? We integrate XRF testing with advanced techniques such as:

- LECO CHN Analysis

- Inductively Coupled Plasma (ICP)

Sample Preparation

At RJ Lee Group, our experienced team prepares samples as fused beads or pressed pellets to ensure optimal accuracy in XRF testing. Depending on your analytical requirements, we can also process loose powders, solids, liquids, or air filter collected samples.

We utilize Malvern Panalytical’s Omnian standardless calibration, alongside dedicated calibrations for common sample types. For specialized projects, we offer custom calibration setups tailored to your unique material composition requirements.

Get in Touch

Contact RJ Lee Group analytical services today to discover how our expert XRF testing, elemental analysis, and non-destructive testing solutions can support your material composition analysis needs. Whether you're in manufacturing, environmental science, or research, our advanced techniques deliver accurate, reliable results tailored to your industry.

Blog

Read More

10 min read

Unlocking the Secrets of Materials: The Power of X-ray Diffraction (XRD) and X-ray Fluorescence (XRF)

October 01, 2024